Data mining – which has evolved from a buzz-word to a real tool, can support in business process and procedure optimization. Learn here how this could be accomplished.

what is process mining?

Process mining is nothing else than data mining for processes. With the gathered data from processes and procedures, steps and handling can be analyzed, adjusted to novel circumstances and optimized.

The goal of process mining is to understand processes by data and through data analysis, optimize these processes for efficiency. But this is not all! Applying risk management principles to the data mining and data analysis opens up the risk-based process design and optimization. Something you should truly care of in the life science.

what do we need to get started?

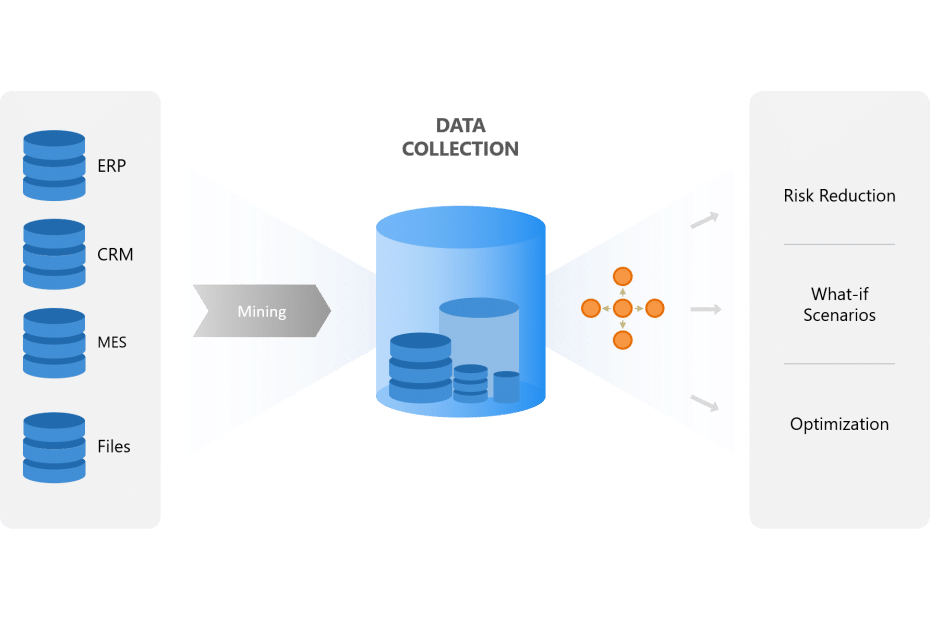

No doubt, process mining is best done with digital business processes, e.g. processes that can be tracked out of Enterprise Resource Planning (ERP), Content Management Systems (CMS), Customer Relationship Management (CRM), Manufacturing Execution Systems (EMS), to name a few. So, digital data is major plus in process mining, but not a must.

Process parameters and times to complete steps are the major concern of process mining. Best practice is to collect the event log data of the software used for processes and mine these data.

how is it done?

Process mining starts at the data of event logs and time stamps. With these data, a visual interpretation of the data can be generated and segregated by time, day, user groups, product, or alike. With the visualization, not only transparency of the processes is crated but the entire process can be shown for further analysis, based on lean or other process optimization processes.

The visualization is used in a second step to analyze the gathered data per step. Systematic review of the process for risks and their reduction, automation potential as well as process compression can be carried out. With large data sets, data mining principles can support the identification of issues and bottlenecks.

After analyzing the data, root-cause analyses, what-if scenarios and other approaches can be used to reduce risks and render processes more effective. Not seldom, artificial intelligence is used in this step to optimize resources and and material flows.

So is this just wishful thinking?

Not at all! Process mining is nowadays a real and utterly effective tool to cut on costs and time consumed on fairly complex processes or company structures. Even at smaller companies, after growth, with established processes or after merger & acquisitions, process mining comes handy to optimize a company and its processes.

Optimization of process by modern technologies and strategies, such as mining, data analysis, artificial intelligence and alike can easily identify the optimization potential, reduce risks or clearly show data discontinuation as changing from a digital to an analog process.

How Avanti Europe can help

Avanti Europe’s Experts have a decade-long track record and expertise in consulting and contracting to the Pharmaceutical and Medical Device industry. Our experts support your company with hands-on workforce and support in risk-based process design, the documentation, training for the company staff. Visit our online shop for checklists and other services.